Brewery equipment holds the key to the art of crafting exquisite brews that tantalize our taste buds. Whether you’re a seasoned brewmaster or simply an enthusiastic beer lover, understanding the intricate world of brewery equipment is essential for unlocking the hidden secrets behind the brewing process. In this comprehensive guide, we will delve into what constitutes brewery equipment, its various components, and explore the fascinating world of microbrewery equipment and beer brewing equipment. So, grab a pint, sit back, and join us on this journey to unveil the mysteries of brewery equipment. Cheers to the craft of brewing!

Understanding Brewery Equipment

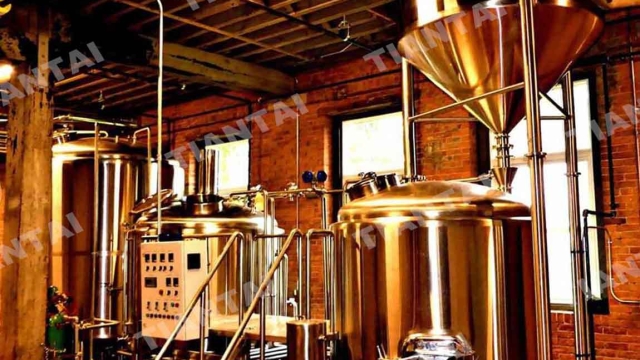

Brewery equipment plays a crucial role in the art and science of brewing beer. Whether it’s a small microbrewery or a large-scale production facility, the right equipment is essential to ensure the perfect brew. In this article, we will explore what brewery equipment entails and how it contributes to the brewing process.

At its core, brewery equipment refers to the machinery and tools used in the brewing industry. From the initial stages of brewing to the final packaging of the beer, a variety of specialized equipment is involved. This includes items such as mash tuns, fermenters, boilers, cooling systems, and filtration equipment. Each piece serves a specific purpose in the brewing process, working harmoniously to create the desired flavors, aromas, and characteristics of the final product.

One important aspect of brewery equipment is its ability to control various parameters throughout the brewing process. Temperature control, for example, is critical during mashing and fermentation stages to ensure the proper enzymatic activity and yeast activity respectively. Many breweries utilize advanced temperature control systems to maintain precise conditions at different stages. Similarly, pressure control is crucial for carbonation and achieving the desired level of effervescence in the beer. With the right equipment, brewers can fine-tune these parameters and create consistent and high-quality brews.

Microbrewery equipment, specifically designed for smaller-scale operations, has gained popularity in recent years. These systems are more compact and versatile, allowing aspiring brewers to experiment and craft unique flavors on a smaller scale. Microbrewery equipment often includes smaller versions of traditional brewery equipment such as mash tuns, fermenters, and cooling systems. This allows for greater flexibility and creativity, enabling brewers to push the boundaries of beer styles and recipes.

In conclusion, brewery equipment is an indispensable part of the beer brewing process. It encompasses a wide range of machinery and tools that contribute to the production of exquisite brews. Whether it’s a large-scale production facility or a small microbrewery, having the right equipment is key to creating consistent, high-quality beers. Understanding the various components and their role in controlling different parameters allows brewers to unleash their creativity and produce a wide range of flavors and styles.

Different Types of Brewery Equipment

In order to produce delicious and high-quality brews, breweries rely on a wide range of specialized equipment. From large-scale commercial operations to small microbreweries, each establishment requires specific tools to craft their unique concoctions. Let’s take a closer look at the different types of brewery equipment that play a crucial role in the beer-making process.

First and foremost, every brewery needs a reliable brewhouse. This is where the magic happens, where the ingredients come together to create the flavorful wort that will eventually become beer. The brewhouse typically consists of several key components, including mash tuns, brew kettles, and hot liquor tanks. These vessels work in harmony to heat, mix, and extract the essential flavors from the malted grains, creating the foundation for the beer.

Once the wort is prepared, it needs to undergo fermentation. This is where fermentation vessels come into play. These tanks, often made of stainless steel, provide the ideal environment for the yeast to convert sugars into alcohol, resulting in a delightful brew. Fermentation vessels can vary in size and design, accommodating the needs of each brewery, whether it’s a large-scale operation or a cozy microbrewery tucked away in a corner of town.

Another vital piece of equipment in any brewery is the filtration system. After fermentation, the beer goes through a filtration process to remove any unwanted particles, ensuring its clarity and stability. Filtration systems can range from simple screens to more complex setups, allowing brewers to achieve the desired level of purity for their brews. This process plays a significant role in enhancing the appearance and taste of the final product.

In conclusion, brewery equipment comes in various shapes and sizes, each serving a specific purpose in the beer-making process. From the brewhouse that brings together the ingredients, to the fermentation vessels that allow the magic to happen, and the filtration systems that refine the brews, every equipment plays a crucial role in creating exquisite brews. Whether you’re a large-scale brewery or a small microbrewery, investing in the right equipment is essential for unlocking the secrets behind crafting exceptional beers.

Choosing the Right Brewery Equipment

When it comes to setting up a brewery, selecting the right equipment is crucial. The brewery equipment you choose will play a vital role in the quality and consistency of your brews. In this guide, we will discuss some key factors to consider when making this important decision.

https://www.micetcraft.com/brewing-equipment/

First and foremost, it’s essential to determine the scale of your brewery operation. Are you planning on starting a small microbrewery or a larger commercial brewery? The size of your operation will dictate the type and capacity of the equipment you need. Small-scale microbreweries may opt for compact and affordable systems, while larger breweries will require larger and more advanced setups.

Next, consider the specific brewing process you want to undertake. Different brewing techniques and styles may require specialized equipment. For example, if you’re planning on brewing traditional ales, you’ll need equipment that can handle the mashing, lautering, and fermentation processes. If you’re interested in experimenting with sour beers, you might want to invest in additional equipment for barrel-aging or souring.

Lastly, budget plays a significant role in choosing brewery equipment. While it’s important to invest in quality equipment to ensure the best possible brews, it’s also necessary to consider your financial limitations. Prioritize equipment essentials based on your budget, and plan for future upgrades and expansions as your brewery grows.

In conclusion, choosing the right brewery equipment is a crucial step in the success of any brewery. By considering the scale of your operation, the brewing processes you’ll undertake, and your budget, you can make an informed decision that sets the foundation for exceptional brews.