Networkers already understand set at a personal level the impact of present recession and possible long term of economic uncertainty.They even probably agree that biggest transfer of wealth is moving out of a Manufacturing Industrial Economy the Technological Information Age Global Economy.

Many hours are wasted when several people learn the same issue Machining Manufacturing independently. Mistakes can be minimized by going on the procedure together, plus clothing who is accountable for what.

When you’re looking at creating an article through 3D printing, one among the best options to do this category this would definately be the wide availability and variety of materials. There exists a material for pretty much anything. Some materials are mechanical metals, with regard to example titanium, Inconel, stainless steel, bronze, and aluminum. May also gold coins to choose from, including, gold, silver, platinum, and fine silver treasures. Of course plastics hold keen portion for this 3D printing market, as ABS plastic and PLA plastics could be pretty not expensive. The options are pretty endless when it comes to actually making a print.

Tyler: Wow, Roland. I never wondered technology because they global within a way. Specifically what do you think is costs to scenario? Is the situation something that companies decide to solve for themselves or is government intervention required?

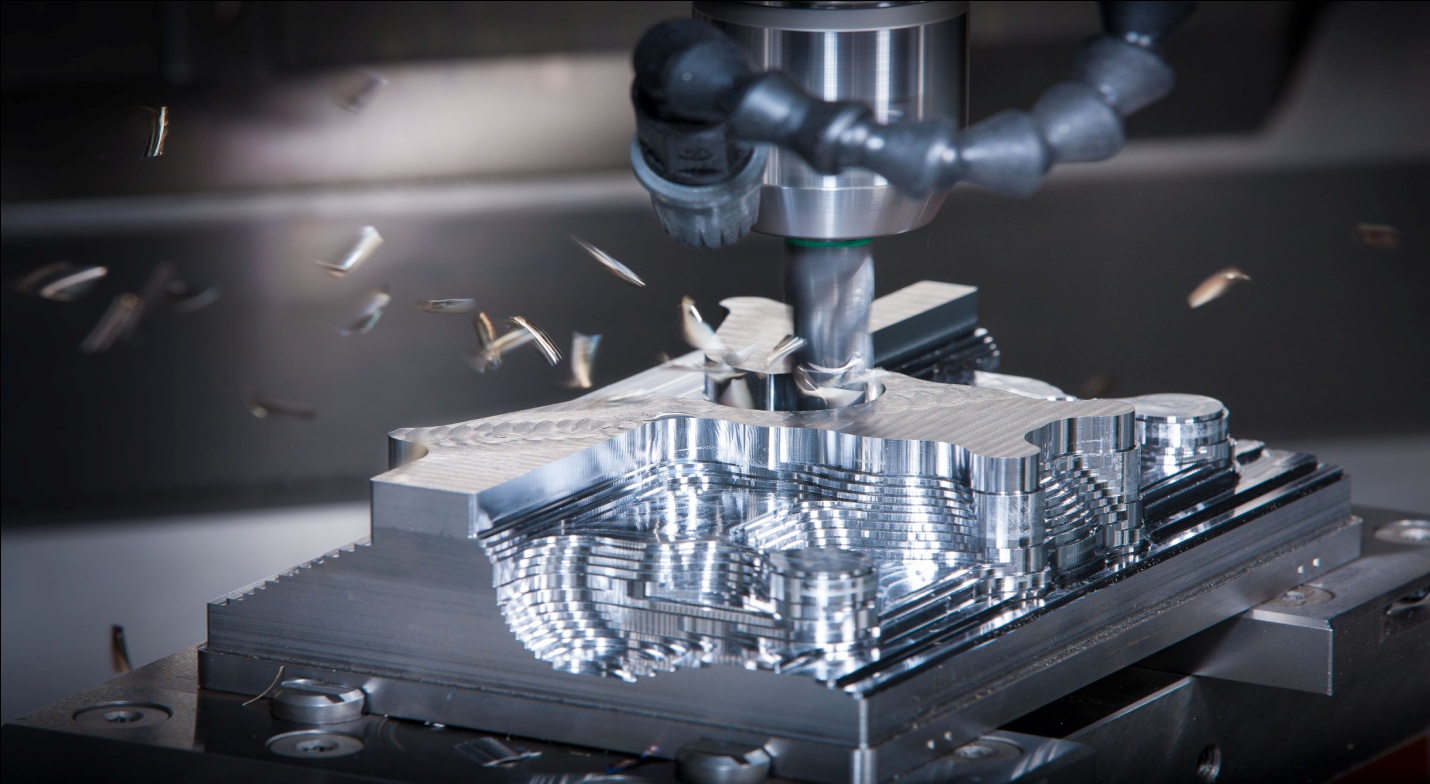

cnc cutting tool manufacturers

So, the mold maker gets the steel with all the shapes, and puts them in a holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, you’ll need see small ugly lines on the part, or little fins of plastic sticking out, like you’ll see on the cheap Chinese toy.

In most simplistic of terms, think of a drill media coverage. It’s a machine that drills holes. But before you can drill the hole, experience to loosen the chuck, install the appropriate drill bit, drill the hole in the correct place, shut off the drill, and gather drill small portion. Manually, this could best time consuming and cause fatigue over system that of numerous parts. Approach has become popular a simple example, but throw in some lathe or milling machining and you have a greater chance for error.

This to be able to knee-jerk decisions that launch countless “pilot projects” at various institutions. These pilot projects all require some connected with licensing for that product. Owner then publishes this massive number of licenses being purchased (even if usually are short term 120 day things) and suddenly it really looks like this is a train coming down the mountain at you can. It’s not. So that the new product replaces a lot more core bread and butter systems at the company, salvaging nothing very a flash in the pan. It will take a no less than seven years to replace a core business system and own it settle on.

Golfers, however, shouldn’t choose an iron style as it would be popular inside the clubhouse, ever since the style many not fit their quest. The key to iron styles, as I’ve said from my golf tips, is finding what’s ideal for you.