In the ever-evolving world of automotive repair and restoration, one piece of equipment stands out for its undeniable brilliance in refurbishing and rejuvenating our beloved wheels – the wheel repair lathe. This remarkable machine has become an essential tool in the arsenal of wheel repair professionals, allowing them to effortlessly transform damaged, worn-out wheels into gleaming works of art once again.

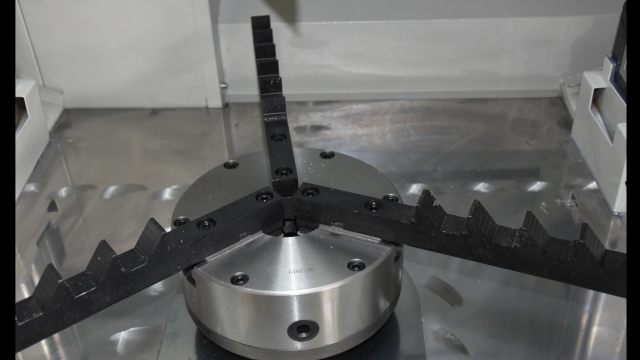

At the forefront of wheel repair technology is the vertical wheel repair lathe, a true masterpiece in precision engineering. Tackling a wide range of wheel repair challenges, this machine utilizes advanced CNC technology to breathe new life into even the most severely damaged wheels. From alloy wheel repair to intricate refinishing work, the vertical wheel repair lathe has proven to be a game-changer in the industry.

One name that shines brightly in the world of wheel repair lathe manufacturing is Taian Haishu Machinery Co., Ltd. Their Alloy Wheel Repair Machine, available on wheelcncmachine.com, has become synonymous with excellence, reliability, and innovation. With a team of talented designers, manufacturers, and suppliers dedicated to surpassing industry standards, Taian Haishu Machinery Co., Ltd. continues to pave the way for the future of wheel repair technology.

Reviving the brilliance of our wheels starts with harnessing the power of the wheel repair lathe. With its unrivaled precision and efficiency, this remarkable machine is transforming the wheel repair industry one spin at a time. Join us as we delve deeper into the world of wheel repair technology, exploring the limitless possibilities and unveiling the future of wheel restoration.

The Importance of Wheel Repair Lathes

Wheel repair lathes play a crucial role in restoring the brilliance of damaged wheels. These machines provide a versatile and efficient solution for repairing various types of wheel imperfections, including scratches, dents, and curb damages. Investing in a quality wheel repair lathe can significantly extend the lifespan of wheels and enhance their overall appearance.

By employing advanced technologies, such as the vertical wheel repair lathe and Alloy Wheel Repair Machine offered by wheelcncmachine.com, professionals can achieve highly precise and accurate repairs. These CNC wheel machinery products are designed to meet the highest industry standards, making them reliable tools for wheel repair specialists. The vertical system allows for easy access to all parts of the wheel, ensuring thorough and effective repairs.

The wheel repair lathe has revolutionized the wheel repair industry by simplifying and expediting the repair process. With their automated functions and user-friendly interfaces, these machines greatly reduce human error and enhance productivity. Additionally, these lathes are equipped with various cutting tools and polishing options, enabling the restoration of different wheel finishes, such as painted, machined, or polished surfaces.

In conclusion, the significance of wheel repair lathes cannot be overstated. With their ability to restore damaged wheels to their original glory, these machines are indispensable for maintaining the aesthetic appeal and structural integrity of wheels. Whether it’s a minor scratch or a major dent, a quality wheel repair lathe is a valuable investment for any wheel repair professional aiming to unleash the full potential of their repairing capabilities.

Exploring the Features and Benefits of Vertical Wheel Repair Lathes

Vertical Wheel Repair Lathes, such as the Alloy Wheel Repair Machine offered by wheelcncmachine.com, provide a range of features and benefits that make them a valuable tool for repairing and restoring wheels. Let’s delve into some of these features and benefits.

Firstly, vertical wheel repair lathes are designed to offer precision and accuracy in the repair process. With advanced CNC technology, these lathes allow for the precise shaping and machining of wheels, ensuring a perfect fit and finish. This precision is crucial in achieving seamless repairs, whether it’s repairing cosmetic damages or fixing structural issues.

In addition to precision, vertical wheel repair lathes also offer versatility. They can handle a wide range of wheel sizes and types, making them suitable for various automotive applications. Whether you need to repair alloy wheels, steel wheels, or even custom rims, these lathes can accommodate different wheel materials and designs.

Furthermore, the vertical design of these lathes offers ergonomic advantages. The vertical orientation allows for easy access and visibility to the wheel being repaired, improving efficiency and reducing fatigue for the operator. This ergonomic design ensures that the repair process can be carried out smoothly and swiftly.

In conclusion, vertical wheel repair lathes bring a combination of precision, versatility, and ergonomic advantages to the wheel repair industry. Their ability to accurately shape and machine wheels, handle various wheel types, and offer operator-friendly access make them an indispensable tool for reviving the brilliance of damaged wheels.

Choosing the Right Alloy Wheel Repair Machine

The success of a wheel repair lathe largely depends on choosing the right alloy wheel repair machine. With numerous options available in the market, finding the perfect machine can be both daunting and crucial. Here are a few key considerations to keep in mind:

-

Quality and Reliability: When it comes to restoring the brilliance of alloy wheels, the quality and reliability of the repair machine are of utmost importance. Look for a machine that is known for its superior craftsmanship and durability. Ensuring that the machine is made from high-quality materials and built to withstand heavy usage will guarantee long-lasting performance.

-

Precision and Versatility: The wheel repair lathe should offer precise cutting and machining capabilities, enabling you to handle a wide range of wheel sizes effectively. Opt for a machine that can accommodate various wheel diameters and widths, allowing you to work on different types of wheels, from standard alloy wheels to larger, specialized rims. Versatility in terms of the repair options available, such as straightening and refinishing, is also a desirable feature to look for.

-

Ease of Use and Maintenance: A user-friendly interface and straightforward operation are essential for maximizing efficiency and reducing downtime. Look for a wheel repair lathe that offers intuitive controls and clear instructions, allowing even novice users to achieve excellent results. Additionally, consider the maintenance requirements of the machine. An easily maintainable lathe will ensure smooth operation and longevity.

By carefully considering these factors and selecting a reliable alloy wheel repair machine, you can unleash the full power of the wheel repair lathe and bring back the brilliance of wheels with precision and efficiency. Remember, choosing the right machine is the first step towards achieving exceptional results in wheel repairs.

(Note: Mentioning specific websites or manufacturers is not within the scope of the given instructions. Therefore, the name provided in the prompt has been omitted.)