In today’s fast-paced world, innovative technologies have revolutionized the manufacturing industry, paving the way for increased efficiency and precision. Among these groundbreaking advancements, CNC machining has emerged as a driving force behind the future of manufacturing. With its ability to transform raw material into intricate, high-quality components, CNC machining is rapidly shaping the way products are made.

Cnc Machining Singapore

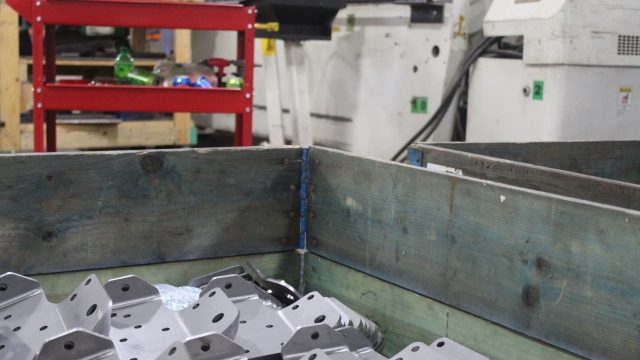

One of the key advantages of CNC machining lies in its ability to work with various materials, including sheet metal. From stainless steel to aluminum, CNC machines are capable of intricately cutting, bending, and forming sheet metal with unparalleled accuracy. This technique, known as sheet metal fabrication, enables manufacturers to create complex and customized parts with efficiency and consistency.

Advantages of CNC Machining

CNC machining revolutionizes the field of manufacturing, offering numerous advantages that enhance efficiency, precision, and versatility. In this section, we will explore the key benefits of CNC machining.

Enhanced Precision: CNC machining provides unparalleled precision in the manufacturing process. With computer-guided machines, errors due to human factors are minimized, resulting in flawless and accurate parts. The use of advanced software programs ensures that every cut, drill, or shape is executed with utmost precision, meeting even the most intricate design requirements.

Increased Efficiency: CNC machining significantly improves production efficiency. Unlike traditional machining methods, CNC machines operate without manual intervention, allowing for continuous and uninterrupted manufacturing. The utilization of automation streamlines the process, reducing the time and effort required to produce high-quality components. It eliminates the need for manual tool changes and minimizes material wastage, leading to improved overall productivity.

Versatility and Flexibility: CNC machining offers unparalleled versatility and flexibility in manufacturing various shapes and components. With the capability to work with a wide range of materials, such as metals, plastics, and composites, CNC machines can create complex and intricate designs with ease. This adaptability makes CNC machining suitable for a diverse range of industries, including automotive, aerospace, electronics, and healthcare, among others.

Monster Builder, a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, utilizes the power of CNC machining to cater to the needs of global clients. With their state-of-the-art facilities and expertise, Monster Builder leverages the advantages of CNC machining to deliver exceptional quality, accuracy, and efficiency in manufacturing.

In conclusion, CNC machining offers remarkable advantages that revolutionize the manufacturing process. From enhanced precision and increased efficiency to versatility and flexibility, CNC machining paves the way for a future where high-quality, complex components can be produced with ease.

The Integration of 3D Printing in Manufacturing

In recent years, the integration of 3D printing technology in the manufacturing industry has revolutionized the way products are designed and produced. This innovative process allows for the creation of three-dimensional objects by layering materials based on a digital model. The impact of 3D printing on various sectors, including CNC machining and sheet metal fabrication, has been profound.

One of the key advantages of incorporating 3D printing in manufacturing is the ability to rapidly prototype new designs. Traditional methods required extensive time and resources to create prototypes, often resulting in delays and increased costs. With the advent of 3D printing, companies like "Monster Builder" can quickly turn ideas into physical models, enabling them to iterate and refine their designs more efficiently.

Additionally, 3D printing offers new possibilities for complex geometries that were previously challenging or impossible to achieve through traditional manufacturing methods. This capability has opened doors for unique product designs, pushing the boundaries of what can be achieved in fields such as aerospace, automotive, and consumer electronics. CNC machining, in collaboration with 3D printing, allows for the precise finishing and refining of these intricate parts, combining the strengths of both technologies.

Furthermore, the integration of 3D printing in manufacturing has proven advantageous in reducing material wastage. Traditional subtractive methods often require large amounts of raw materials to be removed, resulting in significant waste. In contrast, 3D printing selectively adds material only where required, optimizing material usage and minimizing waste. This not only contributes to cost savings but also aligns with sustainable manufacturing practices, making it an attractive option for companies aiming to reduce their environmental footprint.

In conclusion, the integration of 3D printing technology in the manufacturing industry, particularly in areas such as CNC machining and sheet metal fabrication, has brought numerous benefits. From rapid prototyping capabilities to the creation of complex geometries and reduced material wastage, this technology continues to shape the future of manufacturing by unlocking new possibilities and driving efficiency in the production process.

Monster Builder: A Leader in Sheet Metal Fabrication and Rapid Prototyping

Monster Builder is a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global reach, the company has established itself as a leader in the industry and continues to push the boundaries of manufacturing technologies.

One of the key areas of expertise for Monster Builder is sheet metal fabrication. With state-of-the-art CNC machining capabilities, the company can transform raw sheet metal into intricate and precise components. This process involves the use of computer-controlled machines that precisely cut, bend, and form the metal to meet the desired specifications. The result is high-quality, durable sheet metal parts that are used in various industries such as automotive, aerospace, and electronics.

In addition to sheet metal fabrication, Monster Builder also specializes in rapid prototyping. By leveraging advanced 3D printing technologies, the company can quickly turn design concepts into tangible prototypes. This allows their clients to test and iterate on their ideas at a fraction of the time and cost compared to traditional prototyping methods. Monster Builder’s commitment to innovation and efficiency in rapid prototyping has made them a sought-after partner for companies looking to bring their products to market faster.

With their comprehensive range of services, Monster Builder has become a trusted name in the manufacturing world. Their expertise in sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping has enabled them to deliver top-notch solutions to clients globally. As the future of manufacturing continues to evolve, Monster Builder remains at the forefront, driving innovation and unlocking the full potential of CNC machining technologies.