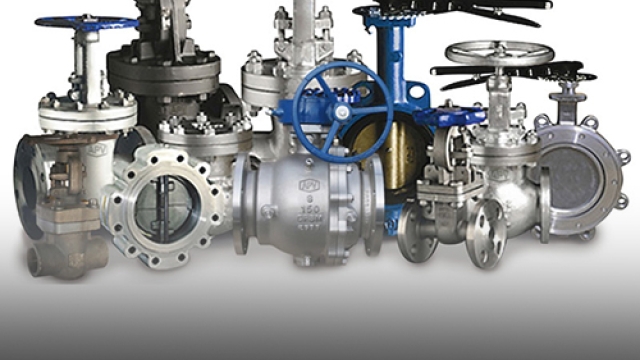

Industrial valves are the unsung heroes behind the smooth operation of countless industries worldwide. These unassuming yet crucial pieces of equipment play a vital role in regulating and controlling the flow of various substances, ensuring the safety and efficiency of industrial processes. From managing water flow in irrigation systems to controlling the passage of gases and chemicals in refineries, industrial valves are the powerhouses that keep operations running smoothly.

One commonly used type of industrial valve is the wedge gate valve. Designed to provide a tight seal against the flow of liquids or gases, this valve offers reliability and durability in various applications. Its unique wedge-shaped disc and gate design allow for a smooth closure, minimizing leakage and preventing fluid or gas loss. This makes the wedge gate valve a popular choice in industries where tight shut-off is crucial, such as oil and gas, water treatment, and power generation.

Another notable type of industrial valve is the flanged gate valve. As the name suggests, this valve incorporates flanges on both ends, allowing for easy installation and connection in piping systems. With its sturdy construction and reliable sealing mechanism, the flanged gate valve is widely used in industries such as chemical processing, petroleum, and wastewater treatment. Its ability to handle high pressure and temperature applications makes it a preferred choice when reliability and efficiency are paramount.

In addition to the wedge gate valve and flanged gate valve, the water gate valve is specifically designed for the control and regulation of water flow. With its robust construction and corrosion-resistant materials, such as cast iron, the water gate valve provides a dependable solution for managing water supply and distribution networks. Its ease of operation and maintenance further contribute to its widespread use in municipal water systems and agricultural irrigation.

The cast iron gate valve is another versatile valve commonly used in industrial settings. Made from durable cast iron materials, this valve offers a combination of strength and affordability, making it an attractive choice across various industries. With its ability to handle high fluid pressures, the cast iron gate valve is often found in applications involving water, sewage, and steam.

In conclusion, industrial valves are the backbone of countless operations, silently controlling the flow of substances that keep industries running. From the reliable wedge gate valve to the easy-to-install flanged gate valve, each type plays a crucial role in specific applications. Whether it’s managing water flow or regulating the passage of chemicals, these valves ensure efficiency, safety, and optimal performance. So, next time you encounter an industrial process, remember the powerhouse behind it all – the industrial valve.

Industrial Valves

Understanding Industrial Valves

Industrial valves play a critical role in various operations across different industries. These valves serve as the powerhouse behind every operation, regulating the flow of fluids such as water, gases, and oils. With their unique designs and functionalities, industrial valves ensure efficient and reliable performance in a wide range of applications.

One type of industrial valve is the wedge gate valve. This valve is commonly used in pipelines where a straight, unobstructed flow is required. Its design consists of a gate that slides between two parallel seats, allowing for full and unimpeded flow when fully open. The wedge gate valve is known for its ability to handle high-pressure applications and its tight shut-off capability, making it a popular choice in industries such as oil and gas, power generation, and water treatment.

Another commonly used industrial valve is the flanged gate valve. This valve is designed with flanged ends that allow for easy installation and maintenance. It features a gate that moves up and down to control the flow of fluids. The flanged gate valve is often used in applications where a tight shut-off and minimal pressure drop are required, making it suitable for use in the chemical, petrochemical, and water industries.

The water gate valve is specifically designed to control the flow of water. It is commonly used in municipal water supply systems, irrigation systems, and fire protection systems. This type of valve allows for precise regulation of water flow, ensuring efficient and reliable water distribution. The water gate valve is typically made from materials that are resistant to corrosion and scale buildup, ensuring its longevity and optimal performance.

Last but not least, the cast iron gate valve is widely used in various industries due to its durability and affordability. This type of valve is made from cast iron, which provides excellent resistance to wear, corrosion, and high temperatures. The cast iron gate valve can be found in applications such as wastewater treatment, HVAC systems, and general industrial processes.

In conclusion, industrial valves are an essential component in the smooth operation of many industries. The wedge gate valve, flanged gate valve, water gate valve, and cast iron gate valve are just a few examples of the wide range of valves available, each with their own unique features and applications. Understanding these valves is crucial for ensuring efficient and reliable fluid control in different industrial settings.

Exploring Different Types of Gate Valves

In this section, we will delve into the world of gate valves and explore the different types that can be found in various industrial applications. These valves play a crucial role in controlling the flow of fluids, allowing or blocking their passage through pipelines or ducts. Let’s take a closer look at three distinct types of gate valves: the wedge gate valve, flanged gate valve, and water gate valve.

The wedge gate valve is one of the most commonly used types in industrial settings. It features a simple but effective design, utilizing a wedge-shaped gate that moves up and down to control the flow of fluids. When the gate is fully lifted, it allows unrestricted flow, and when fully closed, it effectively seals off the pipeline. The wedge gate valve is known for its reliability and durability, making it a popular choice for applications where tight shut-off is required.

Another commonly encountered type is the flanged gate valve. As the name suggests, this valve is equipped with flanges that make it easy to connect to pipes or other components in a system. The flanges create a secure and leak-proof connection, ensuring smooth operation and preventing any unwanted flow interruptions. Flanged gate valves are often preferred in situations where frequent maintenance or replacement may be necessary, as they can be easily dismantled without disturbing the entire pipeline.

Lastly, we have the water gate valve, specifically designed for applications where water flow control is of utmost importance. These valves are commonly used in water distribution systems and irrigation networks. Water gate valves are typically made of materials that can withstand corrosion from prolonged exposure to water, ensuring long-lasting performance. Their design allows for precise regulation of water flow, ensuring efficient and reliable distribution.

By understanding the different types of gate valves available, industries can make informed decisions when selecting the most suitable valve for their specific needs. Whether it’s the reliable wedge gate valve, the versatile flanged gate valve, or the specialized water gate valve, these industrial valves are indispensable powerhouses behind every operation, ensuring the smooth and efficient movement of fluids.

The Versatility of Cast Iron Gate Valves

Cast Iron Gate Valves are a vital component in various industrial operations, providing reliable and efficient control of fluid and gas flow. With their sturdy construction and exceptional durability, these valves have proven to be versatile solutions for a wide range of applications.

One of the key advantages of Cast Iron Gate Valves is their ability to handle different types of fluids, including water, oil, steam, and gas. This versatility makes them an excellent choice for industries such as water treatment plants, oil refineries, power generation facilities, and manufacturing plants.

In addition to their compatibility with various fluids, Cast Iron Gate Valves also offer superior pressure and temperature resistance. These valves can withstand high-pressure environments, ensuring optimal performance even under demanding conditions. Their robust design and reliable sealing mechanism make them ideal for controlling the flow of fluids in both low and high-pressure systems.

Moreover, Cast Iron Gate Valves come in a range of sizes and configurations, making them suitable for different piping systems. Whether it’s a small-scale domestic plumbing system or a large-scale industrial setup, these valves can be tailored to meet specific requirements. Their adaptability ensures seamless integration into existing infrastructure, minimizing installation challenges and maximizing operational efficiency.

In conclusion, Cast Iron Gate Valves have established themselves as a versatile choice for industrial applications. Their ability to handle diverse fluids, withstand high-pressure environments, and adapt to different system requirements make them an essential powerhouse behind every operation that relies on fluid and gas control.